The Taft Industries & A Broad Axe

“After Stephen Taft settled here he began first to build a footbridge across the river and then a Dam to capture water power. In 1794, his younger brother, 16 year old Daniel, came to Taftsville as an apprentice. In August, 1795, they began to build the Sawmill on the North end of the Dam. Next came a Shop on the South side of the river where they began the business of making axes, scythes and other edge tools. Daniel worked in the Sawmill for some time and then began to think about working for himself. In January, 1802, he hired of his brother two fires in the Shop and the use of the Triphammer two-thirds of the time. In August, 1804, then 26 years old, he and another brother Seth purchased the Shop and one-third of the Water Privilege for $260.00. They carried on this business until 1811, when the Shop was destroyed by fire. Seth was fatally injured at the time and died ten days later.

Daniel now purchased the remainder of the Water Right, rebuilt and enlarged the Shop and resumed business alone. His business grew and his scythes sold all over the country. Although other scythe makers stepped in to compete with him, Daniel’s scythes always continued to have the highest repute. The business became a very important manufactory of Agricultural cutlery as well and grew far beyond the conceptions of his brother Stephen who commenced it all.”

Excerpt from Taftsville Tales.

Scythe & Axe Shop and addition.

Taft Industries.

“When Daniel’s sons were grown they went into company with him under the firm name of ‘D. Taft & Sons.’ They purchased stock and tools of Messrs. Granger & Swan who carried on a Furnace business in Woodstock. They set up a new Furnace near the Shop and continued the business of casting ploughs, fire frames and stoves, as well as edge tools, plus smaller items such a stove pokers, broad-axes, pikes, boot jacks, etc. The firm also built many of the houses in the village, of both wood and brick, as well as their own homes.

Beyond the Shop, short distance to the North, were located the Taft Scales which offered splendid service to the community in weighing hay, animals, coals, etc. This has historic importance since it was the last public service rendered by the Tafts.

From 1794 to 1855, for about 61 years, the Taft family ran the whole business and employed many people. The business waxed and waned and eventually came the time when everything was sold off at public auction and the various Shops and Mills passed on through many different owners. Only the Taft house itself remained in the family.”

Excerpt from Taftsville Tales

A Broad Axe from the Taft Industries

Daniel Taft broad axe

Recent acquisition of the

Woodstock History Center

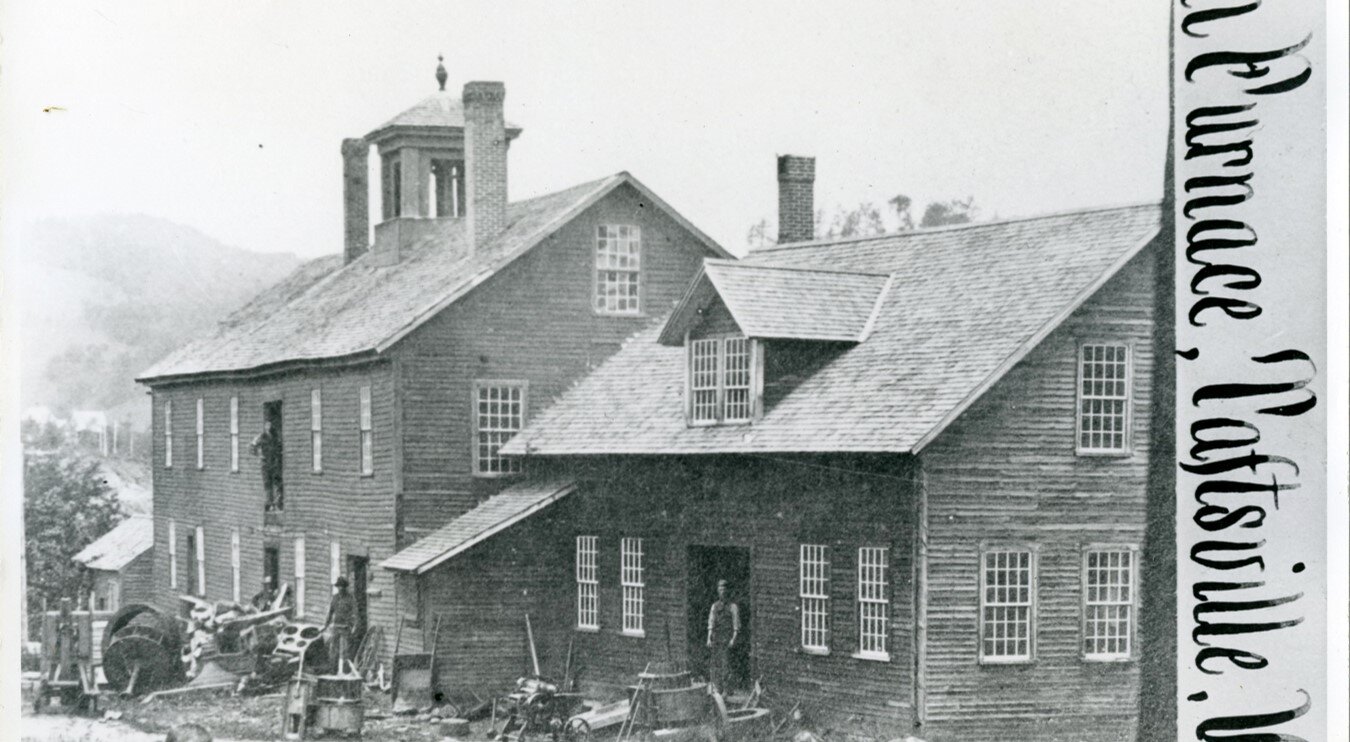

This photo, taken after 1875, shows a much-changed Taftsville after the Taft Industries had been disbanded and assets sold at auction in 1855.

One of most essential tools in early America was the broad axe. The broad axe was used for squaring round logs into beams that would be used in a variety of buildings; including houses, barns, shops, and outbuildings. This tool should not be confused with the felling axe. It is very hard to do so as the blade on a broad axe is nearly twice the size of a felling axe and its handle is much shorter. The broad axe is a substantial tool and the process of “squaring” or “hewing” logs required both hands and skill of the wielder. You can still see the precise marks made by a timber framer on the beams in old buildings.

Beam with broad axe marks in the historic Dana barn.

Enlargement of imprint on early American broad axe.

Stamped: D. TAFT CASTSTEEL

Each letter has been stamped separately in this early stamp mark.

You will see on many of the D. Taft axes a stamp mark that says, “CAST STEEL.” “In the 18th and 19th centuries, the term “cast steel” meant something different than it does today. Back then finished products made of cast steel were NOT cast in a mold like they are today, it was forged. The cast steel of the 19th century was referring to the Crucible process where molten steel was “cast” or poured to make steel ingots within the crucible. Then that ingot was later reheated and forged to make the desired object. Why does it matter? If you see an 19th century axe with a raised seam formed from a mold than it is made of cast iron, not cast steel. All steels have about 1% carbon or less being the reason they are not as brittle as cast iron which is 2-5%.”

This later model of a broad axe has a stamp mark, D. TAFT & SONS CAST-STEEL.

Broad Axe. Collection of the Woodstock History Center.